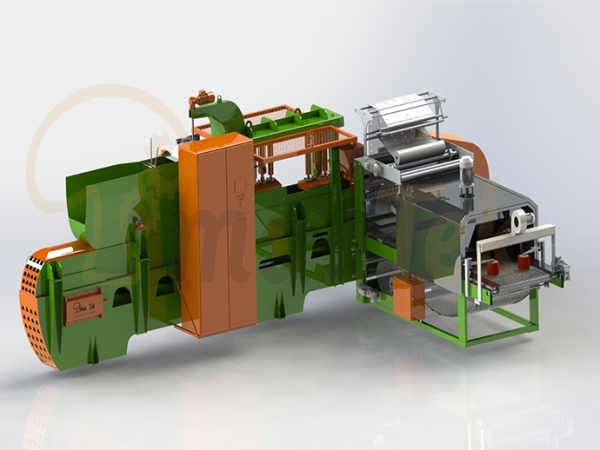

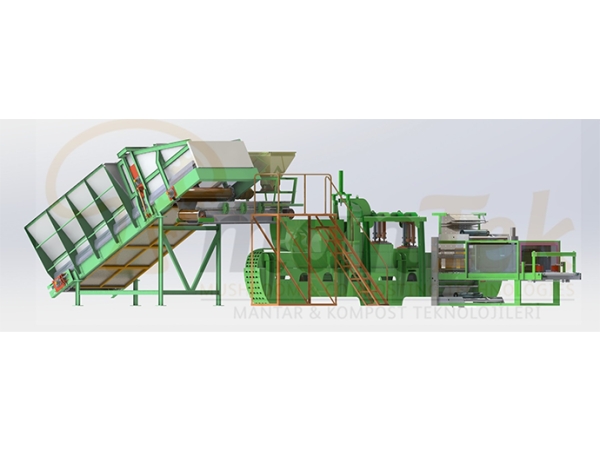

Block Press Machine, the mushroom

compost, which has completed the pasteurization process and is ready to be

transferred to the production room; minimizing the labor cost in hygienic

conditions, it turns the compost into blocks with the block press system and

transmits it to the shrink machine. In the shrink machine, the compost is

covered with nylon film and made ready for shipment and production.

Moisture loss is less in the compost covered

with shrink film, and the compost is prevented from being infected by external

factors during its transportation to the production area.

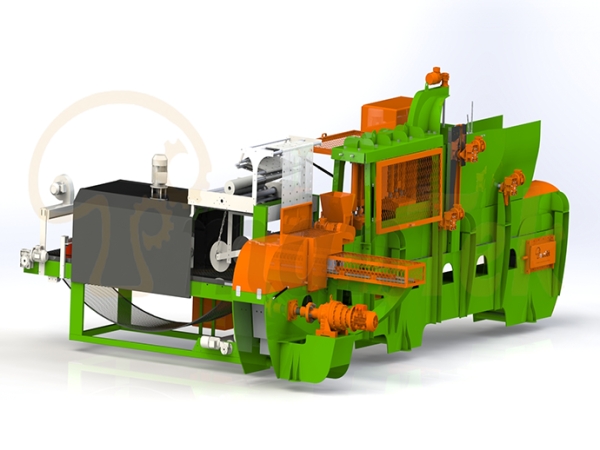

The button mushroom compost is brought into

a regular flowing shape by 1 leveling piston before it is turned into a block

in the block press machine, and it is sent to the press pistons by the leveler,

providing an equal amount of compost. The machine is equipped with two pressing

units. Each pressing unit consists of a hydraulic cylinder and presses the

compost with two (left and right) guide pistons. The block pushing unit ensures

that the blocks are transferred to the packaging unit. In the packaging unit,

the compost is covered with shrink film in the oven insulated with special

stone wool, the packed compost block coming out of the oven is cooled by the

block cooling unit and made ready for transportation.